Lapidary History

Lapidary is the art of shaping stone, minerals, or gemstones into decorative items such as cabochons, engraved gems (like cameos), and faceted designs. But I wondered, how was this done before electric motors and modern abrasives?

Early Lapidary Arts

The earliest known lapidary is from the Neolithic Age (4,000 – 2,000 BCE). Jewelry was made from stones with drilled holes. Bruting was used shape stones. Bruting is done by rubbing a soft stone against another harder stone.

Carved stones, like intaglios and cameos, originated in ancient Greece. The Greeks used stones that could be worked easily with the abrasives at hand and yet were hard enough to withstand daily wear and tear. The most common abrasive in those times was quartz sand which was used to polish agate, carnelian, and lapis lazuli.

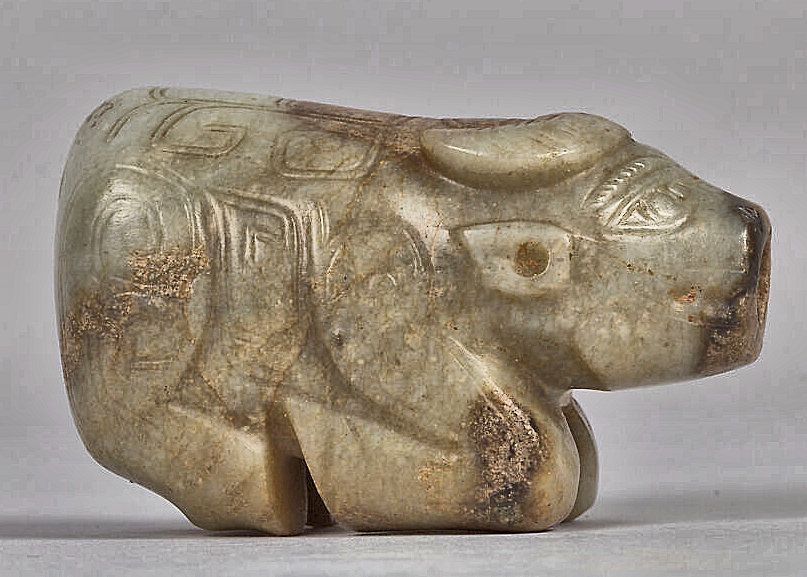

In China, jade carving has been done since about 1550 BCE. Manually-driven rotary carving machines appeared. They featured tools surfaced with stone, wood, and bone. The machines allowed the operator to be seated, and the fixed shaft of the tool to be manually rotated.

The early Egyptians developed cutting methods for lapis lazuli, turquoise, and amethyst. Lapidary was relatively well-developed by 100 CE.

In Europe, garnets were cut by attaching them to stone slabs with a mixture of brick dust and resin. The glued garnets were then held against a rotating horizontal wheel carrying abrasive. Polishing might have been done manually against a wooden block or a smooth piece of copper covered with abrasive powder.

Lapidary was also a tradition in early Mesoamerica. Lapidary items were status symbols, and were used as offerings and burial goods. They were made from jade, turquoise, and greenstones. Aztec lapidarists used string saws and drills made of reed and bone.

Start of Modern Lapidary

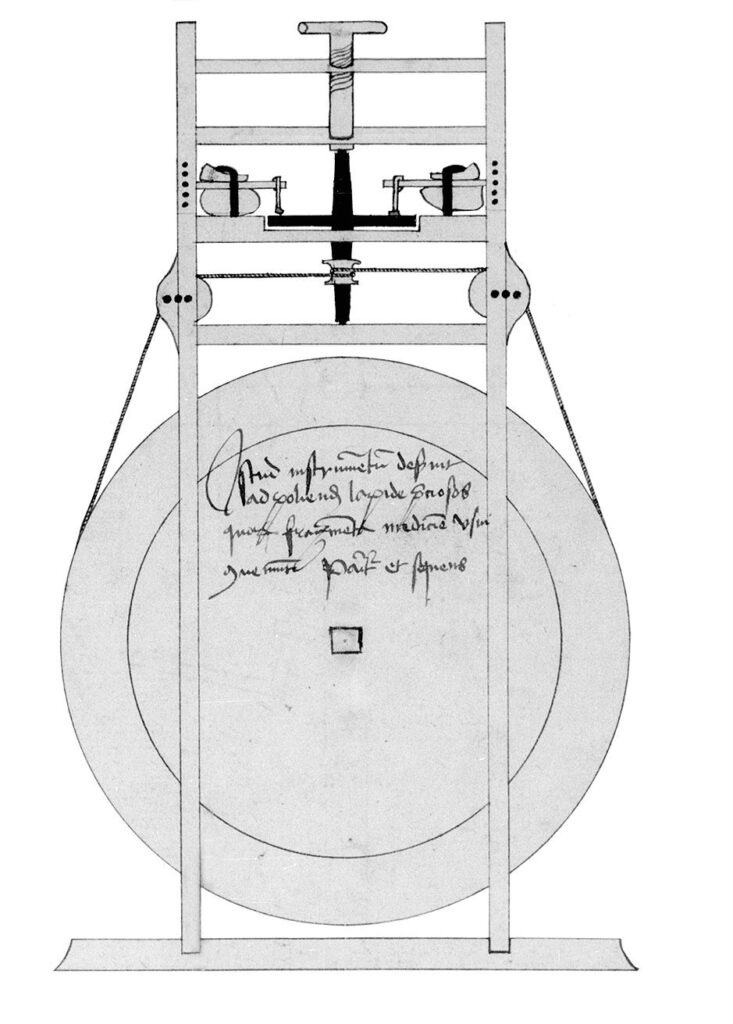

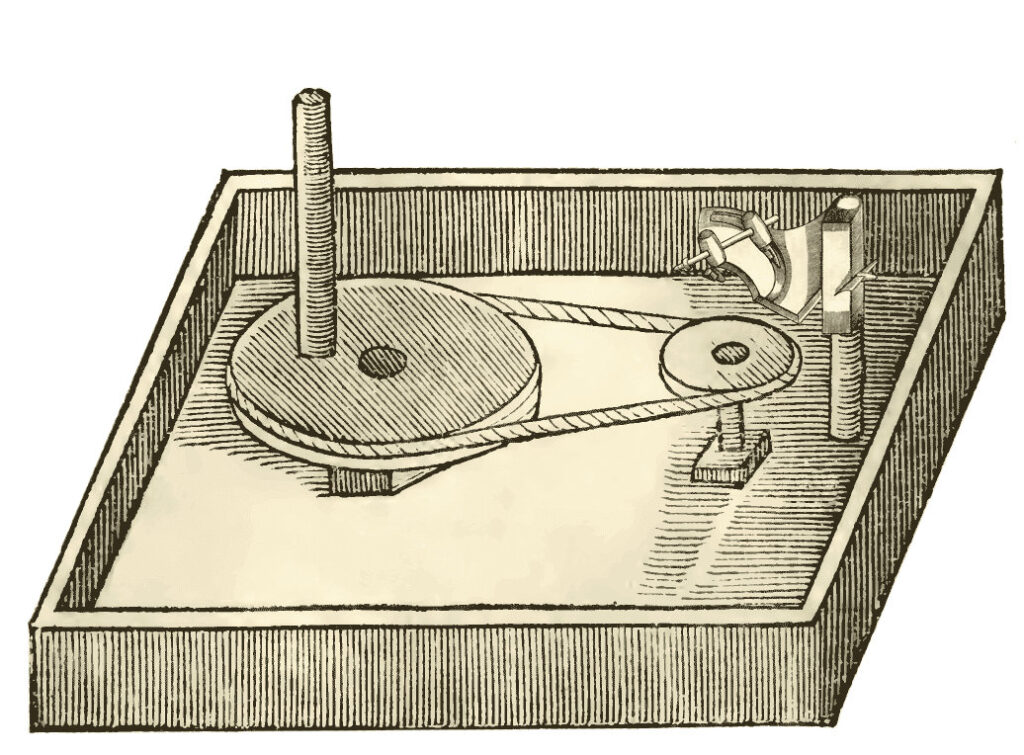

Until the 1400s, stones were cut with an abrasive surface or a hammer and chisel. Lodewyk van Bercken (also known in French as Louis de Berquem) was a Dutch jeweler and diamond cutter. He is credited with inventing the scaif, a horizontal polishing wheel, in the late 1400s.1 A mixture of olive oil and diamond dust was sprinkled onto the rotating wheel made of copper, tin, or lead. The scaif made it possible to polish all the facets of a gemstone symmetrically at angles that best reflected the light.

https://www.gemsociety.org/article/lapidary-technology-history-laps-and-polish

In 1609, another Dutchman named Anselmus Boetius de Boodt began using used emery, sapphire, and ruby as abrasives. Although it took longer to cut stones with these materials compared to diamond abrasives, the abrasives were less expensive and more available.

https://www.gemsociety.org/article/lapidary-technology-history-laps-and-polish

Diamond cutting flourished in France until the French Revolution in 1789, when many cutters fled from France to Holland and Portugal where they continued their work. At the same time in England, lapidaries were cutting colored gemstones, and the towns of Idar and Oberstein became the gemstone cutting and carving center of Germany.

Revolutionary Changes

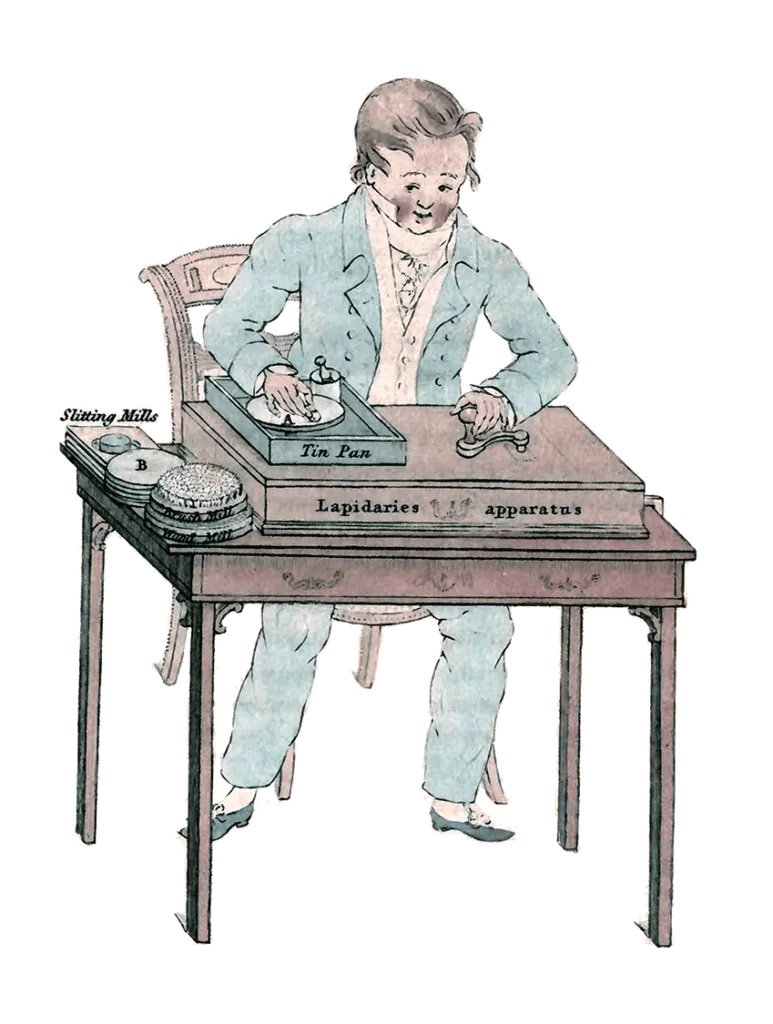

During the Industrial Revolution, new tools to cut stones were developed. In 1765, a convicted Connecticut counterfeiter (!) named Abel Buell patented a lapidary polishing machine. The first portable faceting machine for use by amateurs was invented in 1821 by a British mineralogist named John Mawe.

https://www.gemsociety.org/article/lapidary-technology-history-laps-and-polish

By 1895, stones were cut on hand-cranked laps made of copper, gunmetal, pewter or lead, with silicon carbide or diamond powder used as the cutting abrasive. Polishing was done on hand-cranked wheels made of copper, tin, pewter (a lead alloy) or sometimes wood topped with cloth or leather. The polishing agents used were diamond powder, ruby powder, tripoli, putty powder, pumice or rouge, in all cases mixed with oil or water. The grinding and polishing powders were each applied to separate grinding or buffing wheels.

The 1900s

By the 1930s, laps plated with diamonds made cutting stones easier. Plated laps meant gem cutters no longer had to grind diamond powder, mix it with oil, and apply it to the lap. They could just put the lap on the machine and start cutting. However, the laps wore out quickly.

In 1954, Paul Blackmer patented laps with diamonds sintered into the metal. They were more expensive than other laps, but lasted decades. The sintered laps were too expensive for casual hobbyists, but good for industrial cutting factories. Also in 1954, General Elected created synthetic diamonds, providing abundant and cost-effective diamond powder.

Lapidary became a popular hobby in the United States during the 1950s. Mostly, hobbyists enjoyed creating two types of stonework: cabochons and faceted stones.

Lapidary in the 21st Century

Most modern lapidary work is done using motorized equipment. Polishing is done with resin- or metal-bonded emery, silicon carbide, aluminium oxide, or diamond dust. Often, the final polish will be done with tin oxide or cerium oxide.

There are lapidary clubs throughout the world. In Australia, there are numerous gem shows, including an annual gem show called the GEMBOREE, which is a nationwide lapidary competition. There is a collection of gem and mineral shows held in Tucson, Arizona, at the beginning of February each year. This is currently the largest gem and mineral event in the world.

- While Berquem received the recognition for designing the scaif, there is written evidence that the idea may date to the early 1400s.